We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

What Are Starter Bars?

Construction projects of all types and sizes routinely need to produce concrete slabs and walls, as well as masonry walls, and it’s vital that these slabs and walls are structurally sound and strong enough to meet all project requirements. Steel reinforcement of concrete and masonry is a routine part of construction, in both domestic and industrial projects, and obviously, there are all kinds of steel reinforcement products available, so it’s important to choose the right product for each job, and to understand fully how each product works.

As part of an ongoing series exploring the various steel reinforcement products available in the marketplace today, this article aims to explain what steel reinforcement starter bars are, how they are used, and what to consider when choosing them.

So, Again, What Exactly Are Starter Bars?

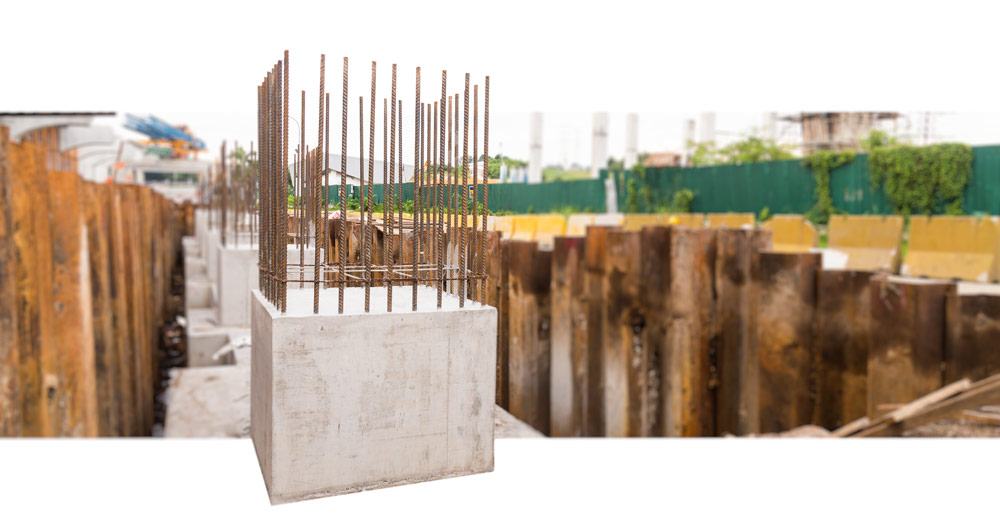

Where a concrete or masonry wall or slab needs to be tied to another element, starter bars are often used to tie the two pieces together in a structurally sound way that maintains integrity and lateral strength. These starter bars are made of reinforcement steel, also known as rebar, and they come in a wide variety of diameters and lengths, to suit all types of construction project. It’s vital to maintain structural integrity at all points in the construction of a building or structure, and starter bars are just one element of steel reinforcement that is used in construction projects. Starter bars are single struts of steel rebar that are fixed into footings, slabs or walls in order to provide a reinforcement overlap when constructing a joining wall or slab. They are typically spaced at fixed intervals and can protrude vertically or horizontally from a slab, depending on what is being joined to an existing element.

Vertically protruding starter bars are relatively simple to handle, as they just stick out from the top edge of the concrete. Where reinforcement is needed along a horizontal edge, it presents a more challenging situation, since any timber formers used to hold the poured concrete in place would need to have holes drilled in exactly the right position for the starter bars to protrude through. Removal of the timber formers would also be made more complicated. In these situations, more sophisticated starter bar solutions may be used.

Safety When Using Starter Bars

Because starter bars are embedded into a concrete slab or wall with one end sticking out, they can present a site safety risk, until the point where the second element is poured or constructed around those starter bars. If you have embedded starter bars vertically in a concrete slab, they could pose a trip hazard and they could also be difficult for drivers of site vehicles or plant machinery to see. For these reasons, protective caps are often fitted to starter bars whilst they are exposed. These brightly coloured plastic caps make the bars stand out much more, so that site operatives can see them easily. As an alternative to using protective caps on starter bars, hooked starter bars are also available, where the sticking out end is looped over, a little like a shepherd’s crook, with the same aim of minimising injuries and accidents on site.

Types of starter bar

There are several different types of starter bar available to meet the needs of all kinds of construction projects. Bars can be straight or L-shaped, and can have the safety hook at one end that we described earlier. They can also be obtained in a range of sizes, or can be custom-made to specific engineering requirements.

There are also a number of more complex starter bar systems, and these are used to deliver the same structural reinforcement in difficult or unusual situations. Where a slab or wall is to be tied to a pre-existing structure, for example, holes can be drilled into the existing concrete, with starter bars then fixed in place using specialist resins. These resins are usually applied into the drilled holes using an applicator gun, and the starter bar is then pushed into the hole using a gentle screwing motion to ensure maximum contact with the resin.

Another option for starter bars is to use screwed bars. With these, the bar that is embedded in concrete has a female screw fixing, or coupler, on one end. When the concrete is poured, this end remains accessible, and once the concrete is poured and any formers have been removed, the ‘sticking out’ bar is screwed firmly into position. This bar has a ‘male’ coupler fitting on one end, to make the connection. These ‘male’ bars are known as continuation bars. For both male and female starter bars, the area where the screw fixing is positioned is thickened, so that there is no loss of structural strength in the bar at that point.

Another starter bar system uses small metal formers that are positioned in the concrete base to create an anchor point - special starter bars then click or screw into these formers, ready for pouring the next concrete element.

Specific Uses For Starter Bars

Reinforcement starter bars are used in a wide variety of construction situations, typically when tying one concrete element to another or tying a masonry wall to a concrete base. Examples include tying walls to footings or concrete slabs, building retaining walls to hold back soil, and creating columns, whether decorative or structural. Obviously, the procedure for building each of these different types of structure varies, and so the most suitable type of starter bar is likely to be different for each project, and advice should be sought from steel reinforcement suppliers if needed, to ensure the right solution is chosen every time.

One reason why the correct starter bar solution needs to be chosen is the issue of potential degradation of the starter bar if it is exposed to water. Leaving starter bars exposed to the elements for prolonged periods is obviously not the best idea, as exposed rebar will rust easily. There are also other situations where exposure to water could be a problem.

As an example, when building a retaining wall, there will obviously be a large quantity of soil or other material up against the wall once it’s constructed. That soil could drive moisture onto the wall, and the join between the slab or footings and the wall itself therefore needs to be sound at all points. A drainage pipe is typically installed behind the retaining wall, once the first layer of blockwork is in position. A geotextile layer would then be added, followed by clean stone. As well as this drainage, the vertical starter bars should be grouted in thoroughly, using specialist grout, in order to protect the starter bar from corrosion. Built properly, there is no reason why retaining walls or other structures should fail due to corrosion of their starter bars.

Conclusion

From the examples given above, it can be seen that using reinforcement starter bars in concrete construction projects is essential to maintain the strength and integrity of buildings and structures and to tie different structures together safely and effectively. Whether you are building retaining walls or columns or simply tying walls to footings or ground slabs, identifying the right steel reinforcement product for your project is key.

Contact us today to discuss your projects in detail and to discover the best reinforcement products for your current job.