We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

What Is a Pile Cap? Everything You Need to Know

Pile caps are hidden structures that prevent buildings from crashing down. These sturdy, load-bearing structures are all around us, supporting every major building.

Pile cap reinforcement might be common, but it can be confusing. Let’s explore the definition, types, and pros and cons of pile caps.

Before you read further...

Are you looking for pile cap reinforcement?

Look no further. Competitive Rates, Experienced Team, and Rapid Delivery UK-Wide.

What Is a Pile Cap?

So, what is a pile cap?

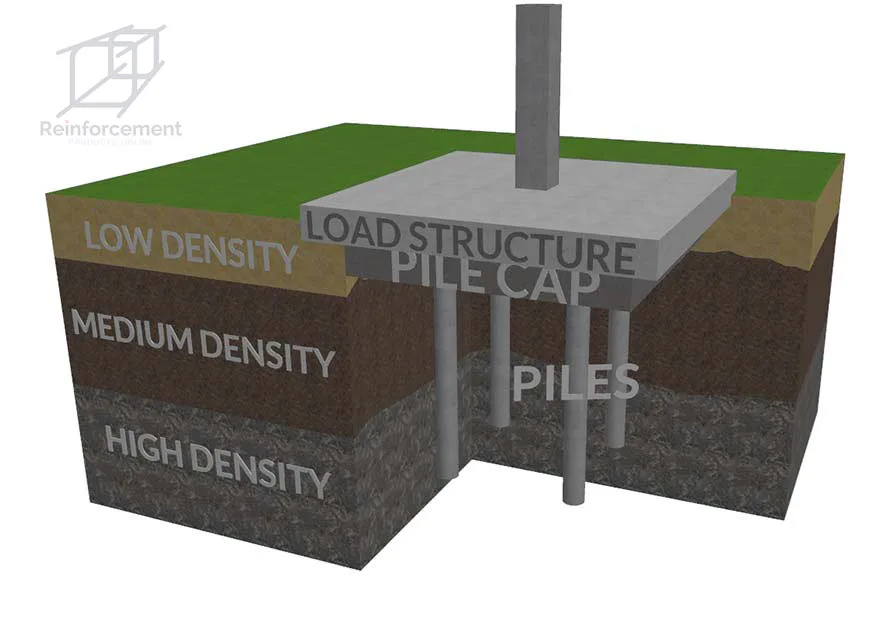

A pile cap (aka capping beam in some applications) is a dense concrete pad that supports heavy structures in areas where the ground is soft. Bridges, hotels, and monuments that sit on top of weak soil might move, lean, or collapse entirely. Pile caps are an industry-standard requirement for soft soils.

How Do Pile Caps Work?

Pile caps start with piles. Piles are long, cylindrical pillars. They are made from lots of materials including timber, steel (normally in the form of rebar), and concrete.

In construction, piles act as the foundations for other structures. The piles are driven into the ground. The goal is to surpass the soft soil and reach hard ground.

When the pile is firmly in the ground, labourers place a thick concrete slab on top. The slab is the “cap.” It acts as the base for any structure placed on it.

Concrete Pile Caps: Pros and Cons

Pile caps tend to be made from concrete, and for good reason. This material has long surpassed timber and steel and is now considered to be one of the best options on the market.

Pros

- Corrosive soils. Concrete acts as a barrier against corrosive soils, whereas wood and steel piles degrade over time.

- Load-bearing. Concrete has excellent load-bearing qualities, making it brilliant for larger structures.

Cons

- Pouring concrete. It is difficult to pour concrete in certain environments, forcing project managers to choose a less robust material.

- Expensive. Concrete pile caps are pricier than the other options.

Wood Pile Caps: Pros and Cons

It is not uncommon for contractors to use timber or wood piles underneath small structures such as bridges. Unfortunately, there are a lot of disadvantages associated with wood piles.

Pros

- Affordable. Wood pile caps are much more affordable to manufacture than concrete or steel caps.

- Easy installation. It might be a stretch to say that the installation process is easy, but at least it doesn’t require heavy machinery.

Cons

- Poor load-bearing qualities. Wood only has sufficient load-bearing qualities to support small bridges and other minor structures.

- Decay. Wood piles deteriorate far quicker than steel or concrete piles, especially when there are toxic substances in the ground.

- Length. It is not a good idea to join two trunks together to create a longer pile, so builders have to work with whatever length is available.

Steel Pile Caps: Pros and Cons

Steel is so strong that it can plough through even the firmest layers of earth. It is a great alternative to concrete.

Pros

- Adjustable. Steel piles have lots of cross-sections, so you can create whichever configurations suit your soil.

- Load-bearing qualities. When we look at the comparative weight of steel and concrete, steel has much better load-bearing qualities.

Cons

- Expensive. Steel is the most expensive of all the materials we have mentioned.

- Corrosion. Steel is susceptible to corrosion and electrolysis, especially if there are high levels of groundwater or low pH balances.

What Are Composite Pile Caps?

Composite pile caps are made from more than one material. The most common configuration is concrete with steel rebar reinforcement, but fibre-reinforced polymer (FRP) caps also go into structures all over the UK.

Project managers might choose to cover their steel piles with concrete casing to protect them from corrosion. Other contractors might extend the length of their wood pile with a concrete pile.

As smart as this idea might seem, it is sometimes difficult to execute. Even the most skilled joiners struggle to seamlessly combine two different materials, especially on the scale necessary to form a pile cap.

Methods of Making Pile Caps

Cast-in-Place Pile Caps Explained

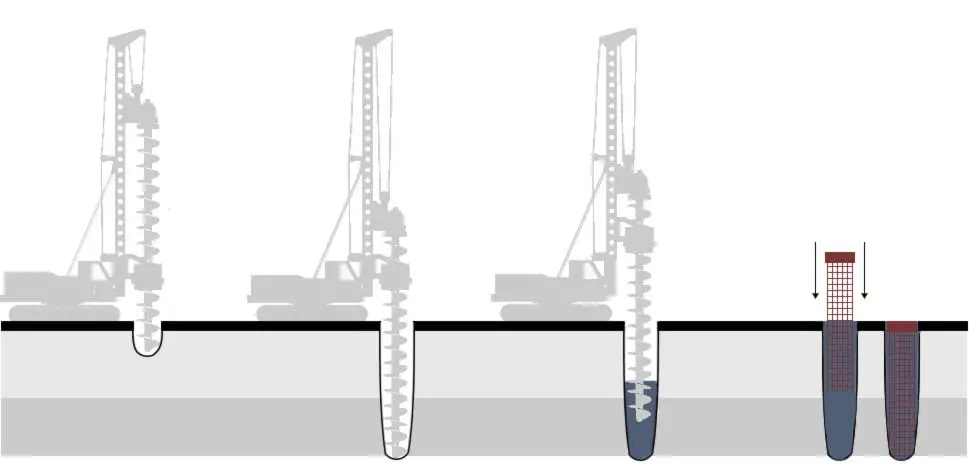

Cast-in-place (or cast-in-situ) pile caps can be either cased or uncased.

To make the cased version, labourers plough a steel shell into the ground and pump concrete into the hole. The shell is filled, and the pile is formed.

To make the uncased version, labourers dig into the ground. Once they have reached their desired depth, they fill the hole with reinforcement, and fill with concrete.

Precast Pile Caps Explained

Precast caps are made to your specifications and delivered to your site. These types of caps drastically reduce the amount of work that needs to happen on-site, which is ideal for contractors who have tight deadlines.

How Deep Do Pile Caps Go?

This table outlines common depths for different pile cap diameters.

| Pile Diameters in mm | Depth of Pile Caps in mm |

|---|---|

| 300 | 700 |

| 350 | 800 |

| 400 | 900 |

| 450 | 1,000 |

| 500 | 1,100 |

| 550 | 1,200 |

| 600 | 1,400 |

| 750 | 1,800 |

Challenges for Pile Cap Reinforcement

Pile cap reinforcement isn’t as straightforward as it might seem. In theory, the pile is buried as far as it needs to go to reach hard ground. But before contractors bury piles, they have to think of all the obstacles.

- TEST item

Here are the factors that can stop your pile in its tracks.

- Punching shear - This is the axial compression force in a pile considering strength load combinations.

- Pile anchorage - This is the length of the bar embedded within the pile below the ground level. It is typically 25-50% of the pile length.

- Weather - Extremely cold weather conditions can halt pile installation projects. Rain can also cause soil to swell, which can displace structures along the way.

- Water table - If the water table is higher than expected, contractors have to reevaluate their strategy. A high water table could strain the piles, potentially causing them to disintegrate.

Order Pile Cages

Prefabricated reinforcement cages are an effective addition to cap any pile. Pile cages strengthen predominantly concrete columns, adding another layer of sturdiness to the already sturdy structure.

We can deliver your pile cage fully assembled, welded, tied, or in separate parts ready for assembly on your site.

Got a question for us? Call us on 01283 205 919 or fill in the online form.