We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Ground Beams in Construction

When it comes to preparing foundations for construction projects, it’s not always possible to adopt a one-size-fits-all approach, and there are occasions where particular foundations aren’t appropriate for the build. In these situations, ground beams can be a fast, accurate and reliable solution, with no discernible difference in bearing strength, longevity or quality. In this article, we examine exactly what a ground beam is, why you might choose a ground beam foundation, and how to reinforce ground beams correctly and safely.

What is a ground beam?

A concrete ground beam is often used in place of other foundation techniques such as concrete footings. Instead of strip or trench footings, a concrete slab, called a beam, is laid on top of piles or pad foundations. Once it is laid and fully dried, the ground beam can support blockwork or brick walls, and in some cases, it can even be used to edge a concrete floor. Ground beams are a popular choice for housing plots of all sizes.

One key advantage of using ground beams instead of other types of foundation is that they can accommodate a wider variation in ground conditions than regular trench footings, making them ideally suited to sites where the terrain is patchy, or where access is restricted. Many ground beams are constructed on site, giving additional flexibility in difficult locations. Other benefits include time and cost savings, since ground beam construction is much faster than other types of foundation work, and it requires a lot less work in the levelling up stage of the process.

Whilst ground beams are very often poured in-situ, that isn’t an absolute necessity, and they can indeed be constructed off-site and then craned into position, for the fastest possible turnaround. This is an increasingly popular option, where time and access are tight.

Ground beam construction

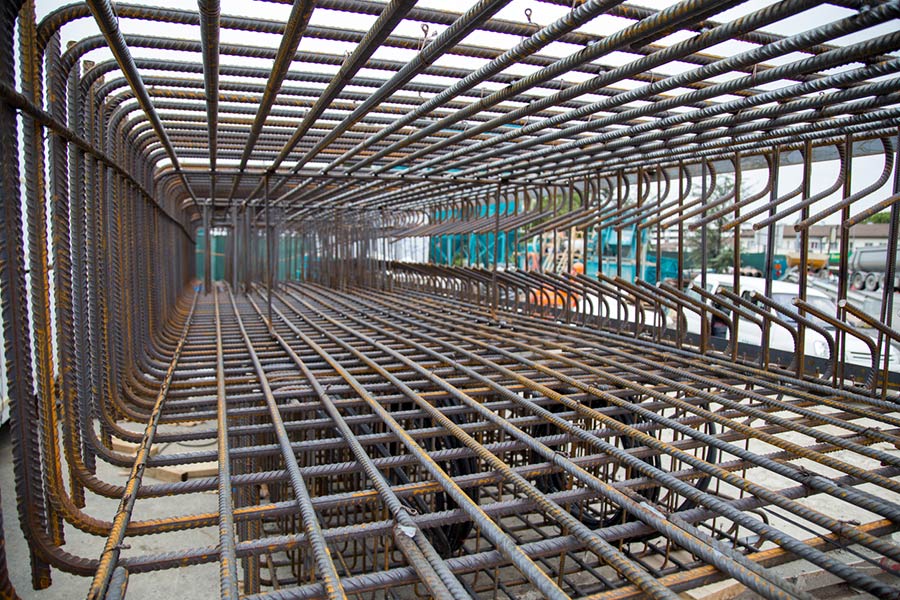

Ground beams are made of reinforced concrete, which rests either directly on the soil or on concrete piles or pad foundations. Once the site excavation has been completed and the pile or pad foundations are in place, formwork is positioned to enclose the entire ground beam area, according to the construction plans. Once everything is in position and the formwork has been checked for size, straight lines and watertightness, the concrete reinforcement should be positioned and tied into place, according to the construction design documents.

At this point, pre-mixed concrete is poured into the formwork, ensuring complete and even coverage at all points. The concrete needs to be compacted and the top surface finished appropriately. The concrete should then be left to go off for a minimum of 24 hours, before the formwork is removed.

Where pre-cast ground beams are used, these are delivered to site ready formed, and are lowered into place by crane. These beams can be stitched together to form a larger surface area, and can also be tied to the pile or pad foundations to secure them.

Reinforcement for ground beams

Like most structural elements that are made of concrete, concrete ground beams require reinforcement in order to give them the tensile strength needed to withstand shearing forces. As we’ve discussed in other articles, concrete on its own has significant compressive strength, but it has relatively low tensile strength. Steel reinforcement works perfectly with concrete to produce a composite material that is able to resist both compressive forces and shearing forces.

Ground beam reinforcement can use traditional rebar or mesh panels, and the choice of reinforcement products will depend on the depth of the beam and the area to be covered. The structural design documents will specify the quantity of reinforcement, the grades of rebar to be used and the depth of concrete below the base reinforcement layer and above the top reinforcement layer. Where the ground beam will rest on pads or piles, these will have ties embedded in them, and the steel reinforcement of the ground beam should be fixed to these ties securely to anchor the beam.

Looking for Steel Reinforcement?

Look no further. Competitive Rates, Experienced Team, Rapid Delivery.

Of course, if you need any guidance or advice on the correct rebar or mesh products for your next construction project, just get in touch with us today for a chat with a member of our friendly and experienced team.

Ground beam formwork

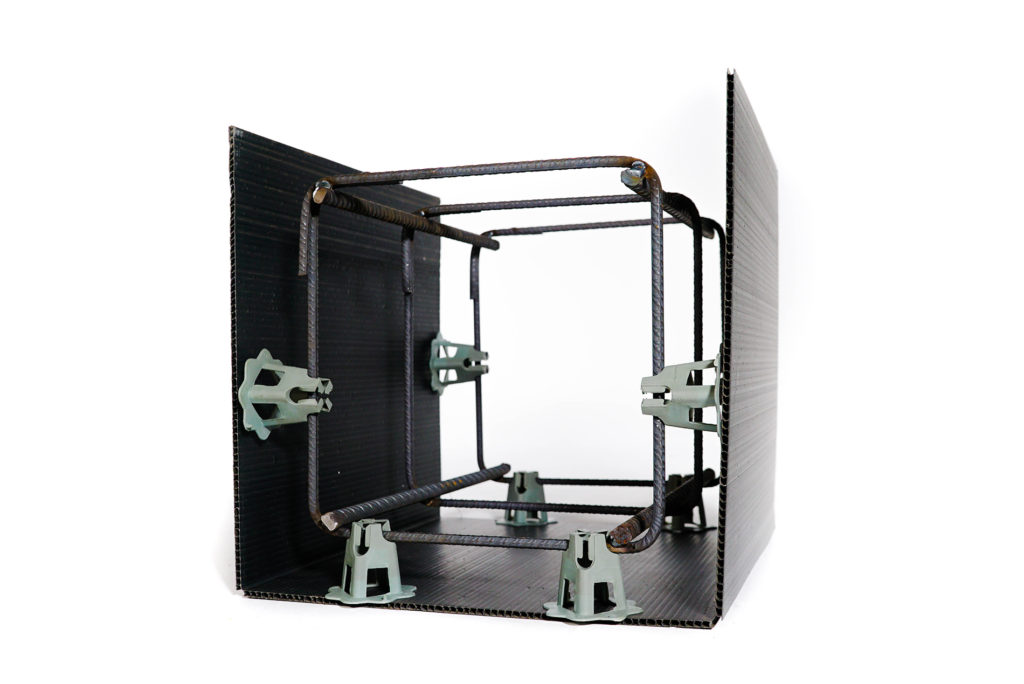

Good formwork is key to producing a reliable and stable ground beam. Beam formwork is usually made up of a three-sided box, in order to provide the necessary structural support and the precise level required. The formwork needs to be strong enough to withstand the hydrostatic pressure exerted by the poured concrete as well as the shear load of the concrete, when wet and when dry.

In order to keep the formwork in place, the area outside of the formwork is back-filled with soil. Formwork can be either temporary or permanent. Obviously, temporary formwork involves more labour, since the formwork has to be removed once the concrete has had time to fully cure.

However, the introduction of new formwork products and techniques has made the construction of concrete beam foundations even easier. One example of such a solution is the Novoform permanent formwork system, which is made of a cold-drawn wire mesh that is coated in a perforated plastic film. Using Novoform formwork is as simple as positioning the U-shaped formwork into the trench, adding the required reinforcement cage and then pouring the concrete. The formwork is permanent and is left in place once the concrete is dry, saving both time and money.

Another alternative to traditional timber formwork is corrugated beamform. This is another plastic shuttering product, which is pre-cut and scored off-site, and then simply lowered into position ready for the reinforcement to be added and the concrete poured. Corrugated beamform is easy to use and simple to cut and form to size, with no specialist skills required. It is lightweight, easy to transport and suitable for all types of ground beam, including steep slopes and curved beams.

Conclusion

As demonstrated above, concrete ground beams offer a fast, flexible and cost-effective solution for projects where other foundation types may not be a good fit. They provide the same high levels of structural integrity as other kinds of foundation, but come with significant advantages in terms of speed of construction, cost of materials, and design flexibility. With pre-cast ground beams also available, this is a foundation solution that is growing in popularity and something that should not be overlooked when designing projects of any size.