We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Reinforced Foundations: Raft Foundation Grades, Overlaps, and Installation Tips

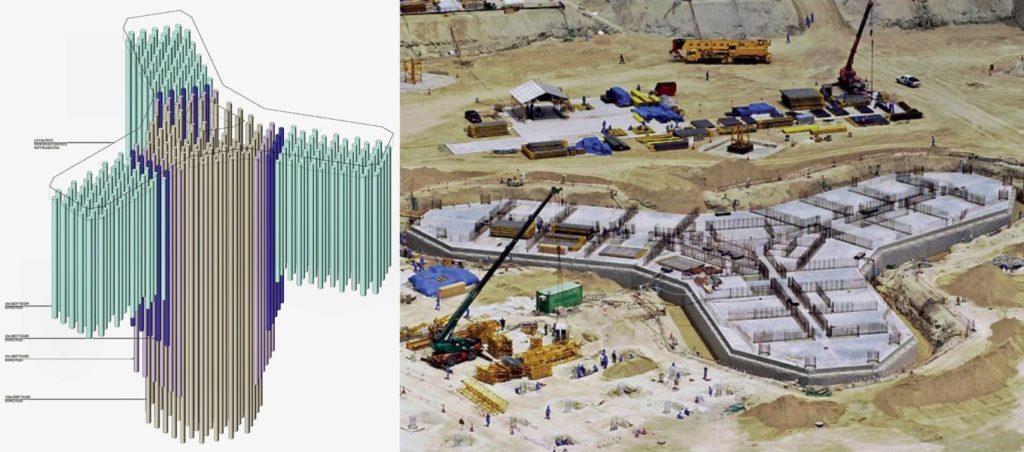

Reinforced raft foundations can support even the heaviest concrete structures, but only if you know your stuff. The (currently in 2024) tallest building in the world, the Burj Khalifa Tower stands on a huge concrete raft foundation, in fact. There are lots of types, grades, and methods of installing reinforced foundations. Let’s look at the basics of foundation rebar and the most important installation tips.

Reinforced Raft Foundations

A raft foundation consists of a concrete slab that sits underneath a structure. Some slabs are uniform, and others are thicker at the edges where columns are located. In some circumstances they are built on piled foundations.

The slab will always be larger than the footprint of the structure. It acts as an even, sturdy base and is often referred to as a ‘floating’ slab.

Ok, here's a basic guide to creating reinforced raft foundations:

- Design the slab

- Dig out the area

- Add formwork

- Add substrate, often gravel

- Place the rebar

- Pour the concrete

- (optional) Have a cuppa

Looking for Steel Reinforcement?

Look no further. Competitive Rates, Experienced Team, Rapid Delivery.

Of course, if you need any guidance or advice on the correct rebar or mesh products for your next construction project, just get in touch with us today for a chat with a member of our friendly and experienced team.

Why Choose Raft Foundations?

Raft foundations are popular in commercial construction projects, such as warehouses and office blocks. In the last few years, homeowners have started choosing raft-reinforced concrete foundations to support conservatories and extensions.

It is not unusual to see rafts in mining zones where the ground can shift from one day to the next. This type of concrete foundation reinforcement eliminates the chance that the structure will be impacted by shifting soil.

This type of rebar structure guarantees excellent structural strength, which somewhat mitigates the expenses accrued by the time-consuming, labour-intensive process.

Raft foundations are considered to be one of the more time-intensive options, but they require far less digging than popular alternatives such as pilings. If you opt for rafts instead of pile caps, you will reduce time and labour expenses. On top of that, the structural concrete slab can double as a floor slab, eliminating a lot of extra work.

Pros and Cons of Raft Foundations

Advantages

- Mitigates ground shift. Perfect for environments where the soil might suddenly shift, reducing the chance of the structure fracturing or sinking into the ground.

- Load-bearing. Can manage massive loads, ideal for heavy buildings.

- Potential cost savings. Possible money savings, if the only other alternative is pile caps.

Disadvantages

- Time-intensive. Large demand on time, meaning projects could run over schedule.

- Difficult to alter. Extremely difficult to alter or enlarge the slab once it has been installed.

How to Choose the Right Foundation Rebar

When it is time to gather materials for your reinforced foundations, you need to choose the right rebar. Rebar comes in all shapes and sizes, and even grades.

Concrete Foundation Reinforcement Grades

In Europe, steel grades start with a letter and end with a number. The letter tells us how we should use the steel, and the number tells us the yield strength of the steel.

For concrete foundation reinforcement, you need grade B rebar. The minimum yield strength for concrete structures is 500MPa. Reinforced steel ends in -A, B, or C.

Difference Between B500A, B500B, and B500C

Each grade of steel has different structural tolerances and styles.

- B500A - smooth, dented, ribbed steel coils, bars, spot-welded reinforcement mesh, and lattice girders

- B500B - dented, ribbed steel coils, bars, spot-welded reinforcement mesh, and lattice girders

- B500C - ribbed coils, bars, and spot-welded reinforcement mesh

If you are looking for reinforced mesh products, B500A steel is your best bet. B500B steel is typically used as a rebar product, and B500C is rarely used. B500C is the most expensive of all the three foundation rebar materials, and it has the fewest forms and uses.

How to Install Raft Foundations

Now that you have the right rebar for foundations, you need to learn the installation tips and tricks of the trade.

Foundation Reinforcement Spacers and Supports

Reinforcement needs to be spaced correctly within the concrete to effectively reinforce the slab. This means you must raise the rebar or mesh off the substrate by the amount defined in your drawings (normally between 50-150mm).

Supports come in concrete, plastic, or steel varieties. Plastic chairs have an advantage over other materials because they are resistant to solvents, oils, and acids. On top of that, they are easy to handle, lift, and transport. That being said, it all depends on your project and the conditions.

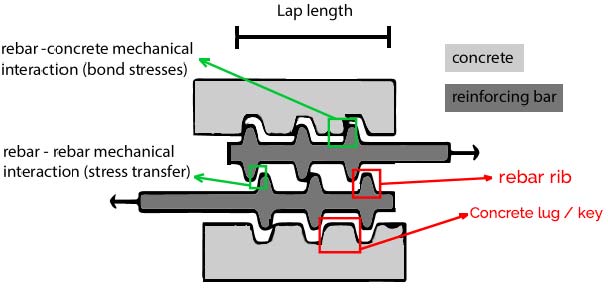

Rebar Overlaps

When creating reinforced foundations, rebar materials such as rebar mesh or rebar rods might require an overlap. In an ideal world, any overlaps will be defined in the construction drawings by a structural engineer. If this is not possible, you need to ensure that there is a minimum overlap of two bars plus 50mm. You should also tie the overlaps with wire binding to reduce the likelihood of movement. Read our guide on lapping mesh reinforcement here.

Concrete Carbonation

Carbonation is a chemical reaction that occurs between carbon dioxide in the air and calcium hydroxide and hydrated calcium silicate in the concrete. As a result, the concrete dries out and cracks.

In short, carbonation can compromise the structural integrity of your reinforced concrete foundation.

Carbonation is more likely to happen when concrete is exposed to the elements during curing, and humidity also plays a large role. Below 25% relative humidity, carbonation is not a problem. But when relative humidity is above 50%, carbonation-induced corrosion can cause concrete to crack and fail.

You can reduce the likelihood of carbonation in a couple of ways.

- Cover the concrete - Place a burlap or frost mat over the concrete to protect it from the elements

- Use a concrete curing agent or sealant - Spray a concrete sealant on newly poured concrete to prevent staining, aid the chemical reaction, and prevent carbonation

Concrete Sealing Agent

SKU RA-SEA-25

- Capacity: 25 Litres

- Non-Staining

Order Rebar Today

Our prefabricated steel reinforcement products are ideal for a range of construction projects; from home DIY extensions, to large scale projects.

Reinforcement Products Online is the easiest, most streamlined way for construction professionals to order concrete foundation reinforcement products. We can deliver standard size, cut and bent, or prefabricated rebar cages and columns in a matter of days.

Call us on 01283 205 919 or email [email protected] to make an order.