We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Concrete Isolation Joints

Thermal movement in concrete slabs (the expansion and contraction of the concrete due to temperature changes) must be taken into account when pouring the concrete to prevent excessive or unwanted cracking. This is usually done with expansion or contraction joints that allow the slab to move. However, there are other situations where you may want to create a joint in concrete slabs, such as when the slab needs to be isolated from another element of the building. Let’s take a closer look at isolation joints.

Why Are Isolation Joints Required?

If a concrete slab was connected to a wall, column or pipe (such as a standpipe or drainage pipe), the slab would crack near these elements as it settles, shrinks or expands. This is because these elements are on their own footings (so are restrained) and don’t move the same way the slab does as they settle or move as the temperature changes. This creates tension within the concrete and will crack the slab, and potentially damage pipes, wiring, or other elements. Every crack in the slab is a weak point, so too many cracks or cracks in the wrong place can cause maintenance or structural issues, as well as creating a rough surface.

What Are Concrete Isolation Joints?

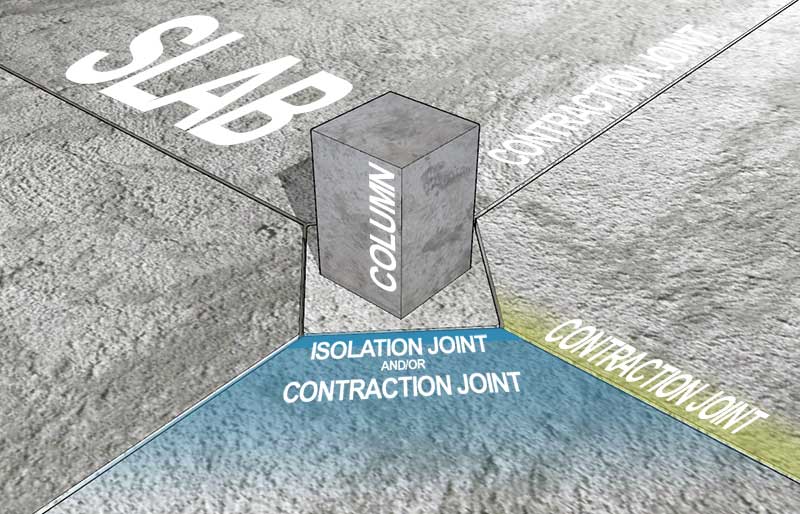

Isolation joints are a gap between the slabs that is typically filled with preformed joint material for the full depth of the slab. This gap completely isolates one slab from another structural member, such as a column, wall or pipe. That way, when the slab moves, it can do so without affecting a nearby column or wall.

For example, if a column settles, it won’t crack the floor slab around it. The preformed joint material can be polyethylene foam insulation, asphalt-impregnated fibreboard, plastic, cork, rubber, or neoprene, and will sit flush with the surface of the concrete slab. Some joint fillers allow the top of the material to be removed so that a gap is left that can be filled with elastomeric sealant.

How Are Isolation Joints Used?

Isolation joints are created by placing the preformed joint material in the desired location before the concrete slab is poured. The slab is then cast with the isolation joint material acting as formwork between the slabs, though unlike formwork, the joint material remains permanently within the slab. When the concrete has cured enough so that it will retain its shape, the top cap of the preformed joint material can be removed (if desired) and the gap filled with sealant.

For example, our K Form Plastic Shuttering Formwork clicks together to create the concrete bay and allows concrete slabs to be poured quickly, acting as both formwork and isolation joint material. The pre-drilled anchor holes keep the K Form anchored within the concrete, while the pre-drilled dowel holes allow easy installation of any dowels between slabs. K Form stays within the slabs, so there’s no time lost stripping and cleaning shuttering, and when the concrete is ready, the 10mm top strip can be removed for joint sealing. For thicker slabs, taller formwork pieces are available – as are removable extension strips – so that slab thicknesses of 140mm or 225mm can be accommodated.

Looking for Steel Reinforcement?

Look no further. Competitive Rates, Experienced Team, Rapid Delivery.

Of course, if you need any guidance or advice on the correct rebar or mesh products for your next construction project, just get in touch with us today for a chat with a member of our friendly and experienced team.

Where Are Isolation Joints Used?

Buildings

You can usually spot isolation joints at a column as the joints will form either a diamond or circle around the column. This completely isolates the column from the slabs around it, so that any movement can be accommodated. Similarly, concrete slabs at walls need to be separated from the wall slabs with an isolation joint around the edge of the slab where it would meet the wall. Other areas that might need isolation joints are where materials change (from concrete to steel, for example), or where temperature conditions change (such as where a heated office adjoins an unheated warehouse area).

Roads and Bridges

Although less common than other joints, isolation joints are sometimes used in roads and bridges where differential settlement is expected (one slab settles or moves differently to the slab next to it), such as junctions (at-grade (on the same level) or grade-separated (one road passing over another)), drainage gullies, manholes, or when there is an existing pavement to tie-in to.

Other Types of Concrete Joints

Isolation joints are just one of the types of joints in concrete slabs, but there are also other types of joints. To learn more, see our articles on expansion joints and contraction joints